Key Technologies of Battery Management System (BMS)

Battery state estimation

Common methods for estimating battery SOC include open-circuit voltage method, internal resistance method, and ampere-hour integration method. Traditional calculation methods usually combine ampere-hour integration with open-circuit voltage closely.

The open-circuit voltage method is simple and accurate, but it is affected by the current volume and is not suitable for single-layer lithium iron phosphate batteries.

2. The method of calculating by integrating over time is very simple, but the integration of current is very prone to accumulate errors.

3. The battery internal resistance method has relatively high charging and discharging precision and adaptability at both ends, but the correlation between internal resistance and SOC is complex, with many influencing factors, and is not suitable for independent application.

The key to the new SOC optimization algorithm lies in the neural network approach and the Kalman filter approach.

Neural network methods have good adaptability and are applicable to various types of batteries, but they require a large amount of data sample self-learning training, and a large amount of computing power and strong integrated circuits to support them.

2. The Kalman filtering method has high precision and can obtain possible deviations in real time, but the second-order physical model with higher accuracy requires a large amount of calculation.

Battery thermal management

There are two functions of battery thermal management methods: heat dissipation and heating of the battery.

1.According to the vehicle regulations, PTC or heating films are commonly used to immediately heat lithium battery cells. The heating efficiency can reach 0.5℃/min, which is more energy-efficient and environmentally friendly than water-cooled heating. For new heating methods such as ACB and high-frequency single pulses, the efficiency is relatively high, but the technology still needs further research.

2. The heat generated by batteries is generally dissipated through natural cooling, evaporative cooling or liquid cooling. Battery cooling usually employs high aspect ratio integrated cooling systems and automotive air conditioning methods.

Battery balancing management

Battery balancing management plays a significant role in addressing the imbalance issue of battery packs, ensuring consistent performance among individual cells within the pack, and thus guaranteeing the driving range and safety of electric vehicles.

1.Passive equilibrium

Since the battery pack is constantly discharging through resistance and releasing heat energy in an invisible way, it increases the burden of battery thermal management. This kind of circuit is mainly used for balancing low-power power supplies composed of lead-acid and nickel-metal-hydride batteries, etc., which have high reliability requirements and sufficient energy supply.

Switched shunt resistor balancing circuit, this circuit adds a controllable switch tube on the basis of the fixed shunt resistor balancing circuit, and only discharges the battery with high charge. Generally, the bypass resistor is adjusted to limit the maximum balancing current to within 100mA. It can be applied to the balancing management of lithium battery packs in electric vehicles. The vast majority of electric vehicles, such as Tesla, adopt this kind of balancing management.

However, essentially, the switch shunt resistor circuit is still a dissipative equalization circuit, and the energy is not reused either.

2. Active Balancing

The active balancing circuit achieves balance by redistributing energy among batteries through energy transfer. With the advantage of reusing the excess energy of batteries, the active balancing circuit has become the main research direction of balancing circuits at present. According to the way of energy transfer, it can be classified into capacitor type, inductor type, transformer type, DC-DC converter type and multi-level converter type, etc.

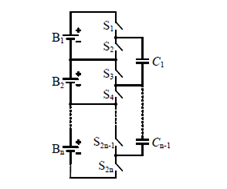

Suppose the battery B1 and battery B2 have different levels of charge, and the charge of B1 is higher than that of B2. To balance the two single-cell batteries, switch tubes S1 and S3 are turned on, while S2 and S4 are turned off. Battery B1 then transfers its charge to the energy storage capacitor C1. After that, S2 and S4 are turned on, while S1 and S3 are turned off, connecting B2 to C1. The capacitor charges B2. This process is repeated to achieve the balance of the two batteries.

High-voltage signal acquisition and analysis

The insulation resistance mainly collects the insulation resistance between the total positive of the battery system and the box body, as well as the insulation resistance between the total negative of the battery system and the box body. The high-voltage interlock includes the interlock status of the high-voltage aviation plug and the interlock status of the MSD.

Charging and discharging management

The BMS linearly interpolates the charging power MAP of the battery system based on the current cell temperature and SOC of the battery system to determine the current maximum allowable charging current of the system.

Discharge management involves the BMS linearly looking up the 10s/30s peak discharge power MAP and continuous discharge power MAP of the power battery system based on the real-time collected temperature and estimated SOC, to obtain the current 10s/30s peak discharge power value and continuous discharge power value of the battery system.

[References: Research on Active Balancing Technology of Battery Management System, Architecture and Development Trend of BMS System for Electric Vehicles]

[Disclaimer] This article is sourced from the "New Energy Era" WeChat official account.