Battery Pack Safety Regulation Testing Solution

I. Industry Background of Safety Testing for Power Batteries

In recent years, with the rapid development of the automotive industry, the number of traditional internal combustion engine vehicles

has increased rapidly, and the contradiction between automotive pollution and sustainable economic and environmental development

has been intensifying. As a typical new type of vehicle, new energy vehicles have received high attention from automakers. Lithium-ion

batteries are mostly used as the energy carriers of new energy vehicles mainly composed of pure electric vehicles. The safety testing of

new energy vehicle power battery systems is a powerful guarantee for ensuring the safe use of lithium batteries.

Safety testing standards are particularly important for enhancing the safety level of power batteries. Based on the sorting out of safety

issues of power batteries, there is an urgent need for corresponding safety technology testing standards. GB/T31467 focuses on the

inspection norms at the battery pack or battery system level. GB/T31467.3-2015 clearly stipulates safety requirements and testing methods.

In summary, in combination with GB/T31485-2015, a complete chemical energy protection specification has been formed, covering battery

cells, modules, power battery packs and power battery systems. Currently, the overall testing standards for power batteries in China are

stricter than those in foreign countries. Through examples, it can be seen that the safety factor of new energy pure electric vehicles is lower

than that oftraditional fuel vehicles, and safety accidents of electric vehicles occur frequently, causing serious casualties and property losses.

In addition,when electric vehicles have accidents, they usually have "special effects" such as fire, sound, light and smoke, which attract

widespread publicattention and doubts. For a pure electric vehicle, the battery cells it uses usually weigh several hundred kilograms.

Taking 100 kilograms of battery cells as an example, the total energy is equivalent to 10 kilograms of TNT. Therefore, in order to prevent

accidents from happening again, the safety testing of battery packs is very important. The safety tests of battery cells in battery packs

mainly include: high temperature,low temperature, short circuit, temperature shock, salt spray, water immersion, vibration, mechanical shock,

compression, and needle puncture.

II. Industry Pain Points

The widespread popularity of new energy vehicles drives the need for progress in the battery industry; when it comes to the testing of

powebatteries, the most important aspect is to ensure their insulation performance is good. When using DC testing, DC voltage is a unipolar

electricity,and the direction of testing the withstand voltage characteristic is also unidirectional. Moreover, the test current is a process

that graduallydecreases until it reaches zero as the capacitor is charged. If the object being tested is not properly connected to the test circuit,

such as an open circuit, it often leads to misjudgment. Additionally, the stable current during the testing of capacitive loads is often

relatively small, making it difficult to identify through setting an upper limit alarm.

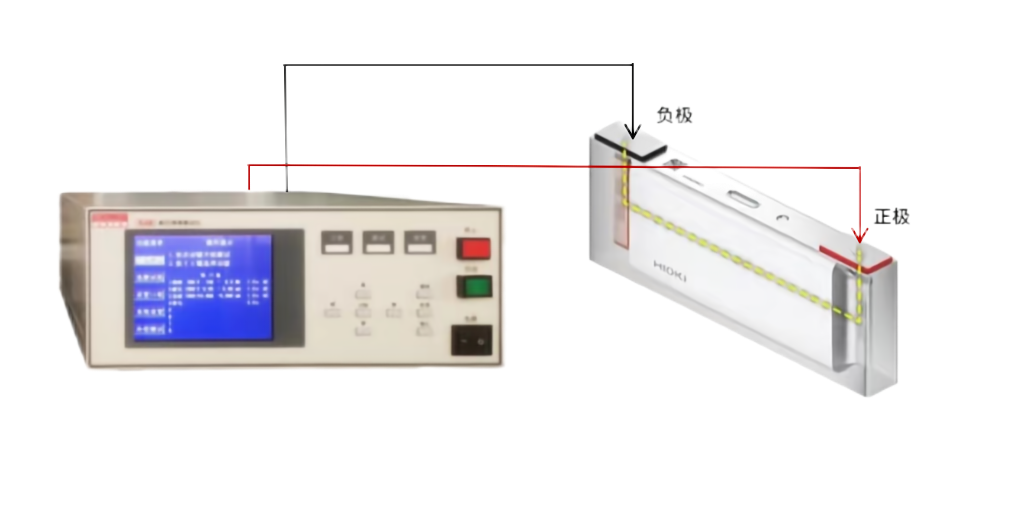

III. Solution

The RJ68 series withstand voltage insulation tester can determine whether the instrument is in an open circuit condition through calculation.

The contact detection function is an important function for performing reliable checks. The contact detection current is the maximum peak

current captured during the voltage output process of the tester. It is generally set for capacitive loads to determine whether the load is open.

During the voltage ramp-up process, the current of the test subject will increase. The tester will automatically record the peak current Ipk during

the ramp-up process. After the ramp-up process ends, it will be determined whether the current peak of the current test is greater than the

user-defined charging lower limit current Icharge. If Ipk > Icharge, it indicates that the load is well connected; otherwise, it is considered an

open circuit, and the tester will alarm.