OBD testing solution

1、 What is OBD?

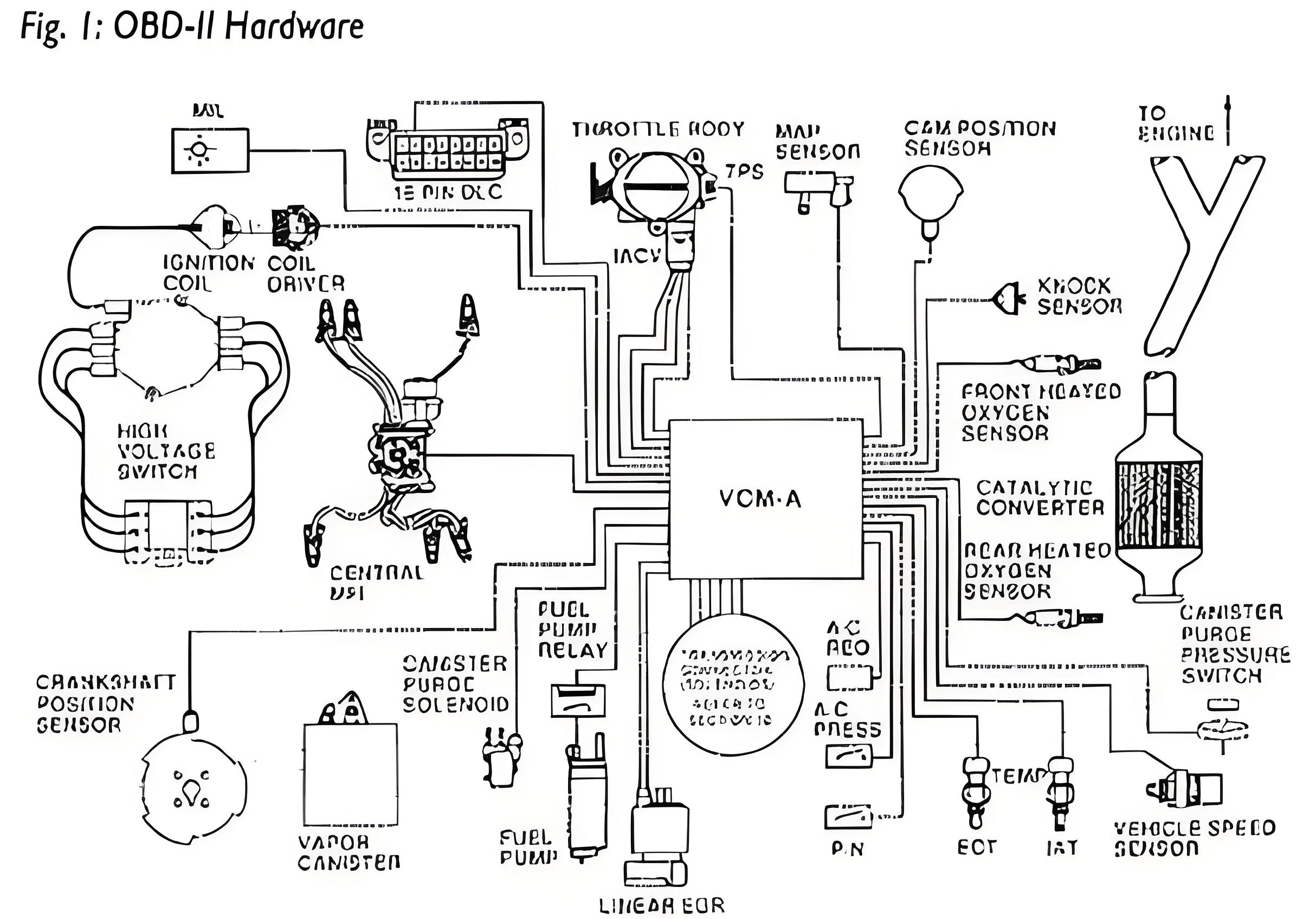

OBD is the abbreviation for On Board Diagnostics in English, translated as "On Board Automatic Diagnostic System" in Chinese. This system will monitor whether the car's exhaust exceeds the standard at any time based on the operation status of the engine. Once it exceeds the standard, it will immediately issue a warning. When the system malfunctions, the MIL light or Check Engine warning light will turn on, and the powertrain control module (PCM) will store the fault information in memory. The fault code can be read out from the PCM through a certain program. According to the prompt of the fault code, maintenance personnel can quickly and accurately determine the nature and location of the fault.

二、OBD功能及其含义

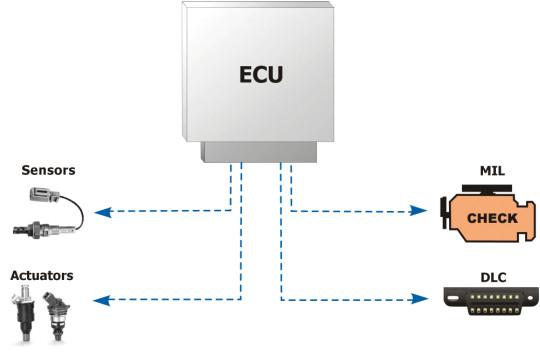

OBD 代表“车载诊断On-Board Diagnostics”。 它是一个基于计算机的系统,最初旨在通过监测主要发动机部件的性能来减少排放。基本的 OBD 系统由一个 ECU(电子控制单元)组成,它使用来自各种传感器(例如氧传感器)的输入来控制执行器(例如燃料喷射器)以获得所需的性能。 “检查发动机”灯,也称为 MIL(故障指示灯),可为车主提供故障预警。 如今的车辆可以支持数百个参数,可以使用称为扫描工具的设备通过 DLC(诊断连接器)访问这些参数。

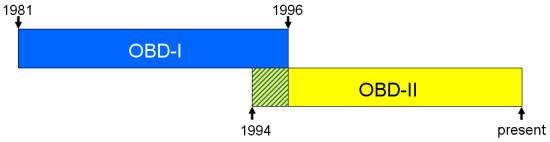

There are two types of onboard diagnostic systems: OBD-I and OBD-II. OBD-IOBD-I refers to the first generation OBD system developed throughout the 1980s. These early systems used proprietary connectors, hardware interfaces, and protocols. To access diagnostic information, it is usually necessary to purchase corresponding tools for each different car manufacturer. The OBD-I scanning tool that supports multiple protocols uses different adapters. In the early 1990s, the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) released a set of standards that described the digital information exchange between ECU and diagnostic scanning tools. All vehicles that comply with the OBD-II standard must use the standard diagnostic connector (SAE J1962) and communicate through one of the standard OBD-II communication protocols. OBD-II was initially introduced in 1994 model year (MY) vehicles and became a requirement for all cars and light trucks starting from the 1996 model year.

3、 Solution

The whole vehicle insulation testing system produced by Ruijie Intelligent integrates equipotential tester, insulation withstand voltage tester, programmable resistance box, multimeter and other equipment. It establishes communication with the vehicle through OBD interface and can perform AC/DC charging port gun seat insulation testing, whole vehicle insulation testing, insulation monitoring function verification, capacitance coupling testing and grounding resistance testing on the vehicle.

After connecting the test gun harness, scan the code to start the test. After the test is completed, the test data can be automatically saved to form a test report, and the test data can also be automatically uploaded through the MES interface.

National standard GB 18384-2020

现场图