High-precision DC resistance testing instrument solution

I. Industry Pain Points

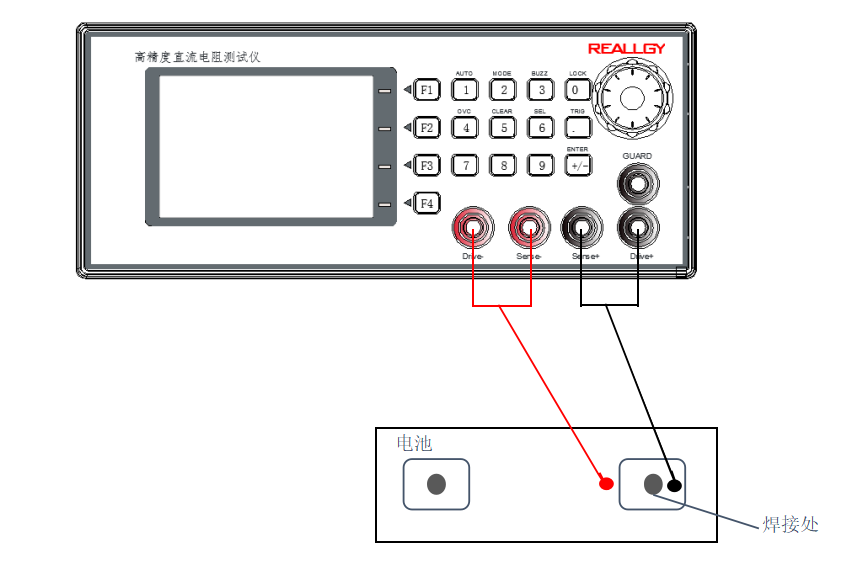

With the rapid development of the power battery industry, the tab, as a component ensuring the conductivity of the battery cell,

if poorly welded, will significantly reduce the efficiency of current transmission. Therefore, how to inspect the welding condition

of the tab has received widespread attention in the industry. Based on the characteristic that current flows more easily to areas

with lower resistance, the resistance varies under different welding conditions. Thus, the welding condition of the tab can be

determined by measuring the changes in resistance. However, due to the shape, material of the battery, and the different test positions,

the resistance often varies by an extremely small amount, making it difficult to measure.

II. Solution

The high-precision DC internal resistance tester RJ3545 developed by Ruijie Intelligent Instruments has a resistance measurement

range of 0.1uΩ to 120MΩ. With a wide measurement range, high speed and high precision, it can measure the extremely small resistance

values after welding, effectively distinguishing the resistance differences of different welding degrees, thereby achieving the identification

of different types of welding conditions. In addition, the RJ3545 can also measure the resistance of coils in motors, transformers,

and contact resistance of relay contacts, as well as the DC resistance of fuses, resistors, and various conductive materials.

It is equipped with an OVC voltage compensation function, making the test results more accurate.